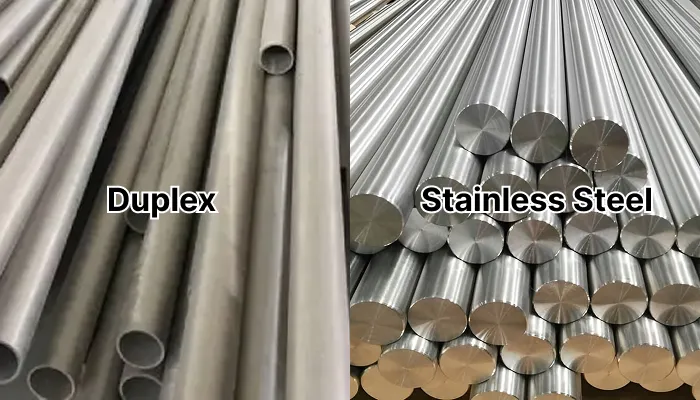

Stainless steels like 304, 316L, and 317L have long been used across industries — but modern engineering demands more:

• Higher pressure

• Higher strength

• More corrosion resistance

• Longer service life

• Offshore & seawater compatibility

This is where Duplex (2205) and Super Duplex (2507 / S32760) outperform traditional stainless steels by a massive margin.

In this blog, we break down exactly why Duplex & Super Duplex steels offer superior strength, where they are used, and how they reduce failures in critical applications.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Duplex vs Stainless Steel Strength | 2025 Super Duplex Guide

Duplex vs Stainless Steel Strength | 2025 Super Duplex Guide

Duplex & Super Duplex Have Double the Strength of Austenitic Stainless Steel

Tensile Strength (Typical Values)

| Alloy | Tensile Strength |

|---|---|

| 304 Stainless Steel | ~550 MPa |

| 316L Stainless Steel | ~580 MPa |

| Duplex 2205 | 620–800 MPa |

| Super Duplex 2507 | 800–950 MPa |

📌 Super Duplex 2507 is almost 2X stronger than 316L.

Stronger materials allow engineers to design:

- Thinner sections

- Lighter structures

- Stronger offshore components

Yield Strength Advantage

Yield strength determines how much load a material can take before permanent deformation.

| Alloy | Yield Strength |

|---|---|

| 316L | 200–300 MPa |

| Duplex 2205 | 450 MPa |

| Super Duplex 2507 | 550 MPa |

📌 Duplex = 2X the yield strength of 316L

📌 Super Duplex = nearly 3X stronger

This strength is important for:

- High-pressure piping

- Structural offshore components

- Riser systems

- Subsea manifolds

Superior Fatigue Strength

Duplex steels resist vibration, cyclic loading, and dynamic stress better than 304/316.

Why?

Their ferrite + austenite microstructure absorbs energy and prevents crack propagation.

Used in:

- Pumps

- Turbines

- Offshore risers

- Ship propeller shafts

- Pulp & paper rotating equipment

Better Stress Corrosion Cracking Resistance

Austenitic stainless steels (304 / 316L) fail quickly when exposed to:

- Warm seawater

- Chlorides

- Tensile stress

Duplex steels have built-in immunity to SCC, especially Super Duplex 2507.

Impact Toughness

✔ Duplex 2205 — Good low-temperature impact performance.

✔ Super Duplex 2507 — High toughness + high strength, ideal for Arctic offshore platforms.

Strength-to-Cost Ratio

Compared to nickel alloys like Inconel or Hastelloy:

- Duplex steels are much more affordable

- Strength almost comparable in many conditions

This makes them ideal for large-scale industrial projects.

Where High Strength Matters Most

Industries relying on Duplex & Super Duplex strength:

- Oil & Gas Offshore Structures

- Desalination Plants

- Subsea Pipelines

- Chemical Processing Units

- Power Generation

- Water Treatment

- Marine Engineering

Components:

- Pressure vessels

- Heat exchangers

- Riser pipes

- Valves, pumps, and flanges

- Load-bearing offshore structures

Conclusion

Duplex and Super Duplex stainless steels offer unmatched strength, durability, and corrosion resistance.

Their ability to outperform 304/316 in harsh, high-pressure environments makes them the preferred choice for modern engineering projects in 2025.

For high-strength materials that deliver long-term reliability,

Moksh Tubes & Fittings LLP provides certified Duplex and Super Duplex pipes,

tubes, fittings, and custom fabrications.

FAQ's

Why is Duplex stainless steel stronger than 304/316?

Because of its dual-phase microstructure (ferrite + austenite), which gives it double the strength and superior crack resistance.

Is Super Duplex stronger than Duplex?

Yes. Super Duplex 2507 has higher Chromium, Molybdenum, and Nitrogen, making it significantly stronger and more corrosion-resistant.

Can Duplex replace carbon steel in high-pressure systems?

Yes — especially where corrosion is present. Duplex steels offer high strength plus corrosion resistance, making them better than carbon steel.

How does temperature affect the strength of Duplex steels?

They retain good strength at high temperatures and excellent toughness at low temperatures, making them suitable for cold-climate offshore installations.

Why do offshore engineers prefer Super Duplex?

Because it offers: Extreme corrosion resistance Highest strength among stainless steels Long-term durability in seawater Excellent fatigue & SCC resistance

Recent Blogs

-

Why Nickel Alloy Bars Are Used in High-Temperature Industries

December 11, 2025

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.