In 2025, as industries push for longer equipment life, higher wear resistance,

and precision movement under high loads, EN31 bearing steel has emerged as a crucial material.

EN31 is a high-carbon alloy steel known for:

• Exceptional hardness

• Outstanding wear resistance

• High compressive strength

• Ability to maintain dimensional accuracy

• Long service life under rolling & sliding contact

It is one of the few engineering steels capable of handling extreme mechanical stress,

making it ideal for bearings, gears, tools, shafts, fasteners, dies, and precision components.

This guide explains why EN31 is considered the ultimate bearing steel, how it compares

to common grades, and where industries use it the most.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

EN31 Bearing Steel Guide 2025 | Properties & Applications

EN31 Bearing Steel Guide 2025 | Properties & Applications

What Makes EN31 Special?

EN31 belongs to the family of high-carbon chromium-bearing steels. Its typical composition includes:

- Carbon: 0.90–1.20%

- Chromium: 1.0–1.6%

- Manganese: 0.30–0.75%

- Silicon: 0.10–0.35%

Why this matters:

- High carbon → extreme hardness

- Chromium → wear resistance + strength

- Clean microstructure → precision movement

EN31 can be induction hardened or through hardened to reach hardness levels of 60–63 HRC, making it one of the hardest engineering steels available.

Mechanical Properties — Hardness Is Its Superpower

| Property | EN31 |

|---|---|

| Tensile Strength | 850–1000 MPa |

| Hardness (Annealed) | 200–250 HB |

| Hardness (Hardened) | 60–63 HRC |

| Wear Resistance | Very High |

| Compressive Strength | High |

| Fatigue Strength | Excellent |

Summary:

- EN31 is designed for maximum surface hardness + wear resistance

- Ideal for rolling, sliding, high-friction applications

EN31 vs EN24 vs EN19 vs EN8 – Quick Comparison

| Grade | Strength | Hardness | Wear Resistance | Impact Toughness |

|---|---|---|---|---|

| EN8 | Medium | Low–Medium | Medium | Medium |

| EN9 | Medium–High | High | High | Moderate |

| EN19 | High | High | High | High |

| EN24 | Very High | Very High | High | Very High |

| EN31 | High | Extremely High | Extremely High | Medium |

✔ EN31 beats all others in hardness & wear resistance

✔ EN24 beats EN31 in toughness

Heat Treatment Performance

EN31 responds extremely well to heat treatment due to its high carbon content.

After heat treatment, EN31 becomes:

- Ultra-hard (up to 63 HRC)

- Highly wear resistant

- Strong under compression

- Resistant to micro-abrasion

Common heat treatments:

- Hardening

- Tempering

- Case hardening

- Induction hardening

This makes EN31 the most preferred material for bearings and precision tools.

Industrial Applications of EN31

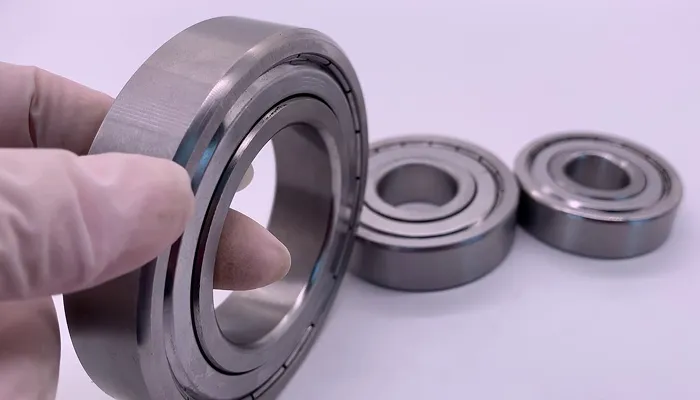

Bearing Manufacturing

- Ball bearings

- Roller bearings

- Needle bearings

- Bearing races

Its hardness ensures long rolling life.

Gears & Transmission Components

- Gearboxes

- Motor systems

- Industrial drivetrains

High wear resistance ensures smooth engagement.

Automotive Components

- CV joints

- Transmission rollers

- Wear plates

- Precision shafts

EN31 maintains dimensional accuracy under stress.

Tool & Die Manufacturing

- Punches

- Dies

- Forming tools

- Cutting tools

Its hardness ensures long service life.

Rolling & Sliding Components

- Guide rails

- Conveyor rollers

- Machine slides

- Linear motion parts

These components demand wear resistance & low surface deformation.

Heavy Machinery & Equipment

- Hydraulic pistons

- Industrial shafts

- High-load pins

- Bearing housings

Advantages of EN31 Steel

- ✔ Extreme hardness

- ✔ Exceptional wear resistance

- ✔ High fatigue strength

- ✔ Strong load-bearing capacity

- ✔ Excellent dimensional stability

- ✔ Long working life in frictional environments

EN31 is one of the few materials that can handle continuous rolling or sliding friction without deformation.

Limitations of EN31

- ⚠ Low impact toughness — not ideal for shock loads (Use EN24)

- ⚠ Difficult machinability after hardening

- ⚠ Poor weldability due to high carbon content

- ⚠ Low corrosion resistance — requires coating/lubrication

EN31 Material Selection Checklist

Choose EN31 if your application involves:

- Continuous rolling motion

- Sliding wear

- Precision fits

- High compressive load

- Long-term durability

- Tooling operations

Avoid EN31 if:

- Shock loads are expected

- Corrosion environment is severe

- Welding is required

Conclusion

EN31 is truly the ultimate bearing and high-wear steel, designed for applications

where hardness, wear resistance, and precision are critical.

While engineering steels like EN8, EN9, EN19, and EN24 serve general strength needs,

EN31 stands alone for:

• Rolling contact fatigue

• Abrasion resistance

• High surface hardness

• Long-term wear performance

For industries that cannot afford dimensional change or wear failure,

EN31 delivers unmatched reliability.

Moksh Tubes & Fittings LLP supplies premium EN31 bars, rods, sheets, tubes,

and machined components for global industrial applications.

FAQ's

Is EN31 good for shafts?

Yes — but only for precision or wear-critical shafts. For high-impact shafts, EN24 is better.

Is EN31 stronger than EN24?

EN31 is harder, but EN24 is tougher and stronger under shock loads.

Can EN31 be welded?

Not recommended — high carbon content leads to cracking.

What hardness does EN31 achieve after treatment?

Up to 60–63 HRC, one of the highest among engineering steels.

Where is EN31 used the most?

Bearings, rollers, dies, tools, gear components, and precision machinery.

Recent Blogs

-

Why Nickel Alloy Bars Are Used in High-Temperature Industries

December 11, 2025

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.