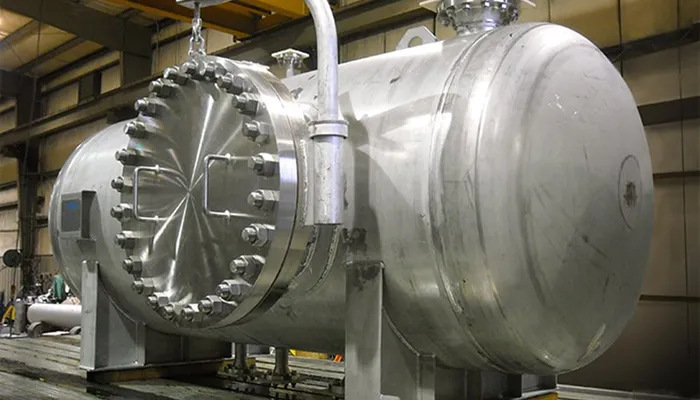

Pressure vessels are among the most critical components used in chemical plants, oil & gas facilities, refineries, power plants, pharmaceuticals, food processing, and water treatment plants.

They store or process fluids under pressure — often at high temperature, high chemical exposure, and high internal stress. Any failure can lead to:

- Plant shutdown

- Safety hazards

- Environmental risk

- Costly repairs

- Major production loss

That’s why fabricated pressure vessels must be designed, engineered, and manufactured with precision, following strict global standards.

This guide explains:

- What pressure vessels are

- How they are designed

- Best materials

- Fabrication process

- Safety standards

- Testing

- Applications

- Why Moksh Tubes is trusted globally

Explained in simple, human-friendly English.