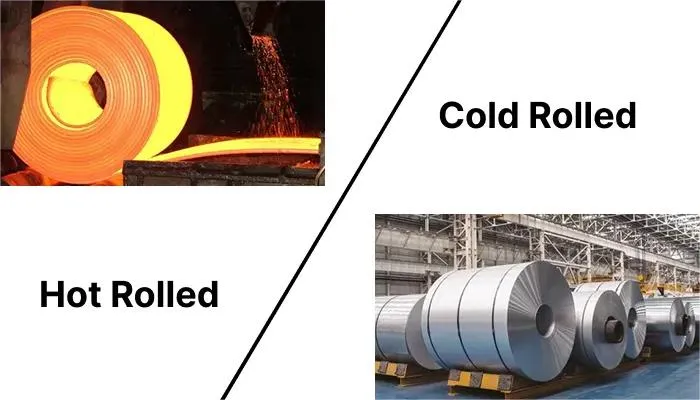

Hot rolled bars and cold drawn bars are essential in engineering, construction, automotive, fabrication, machinery, oil & gas, and industrial projects. One of the most common confusions among engineers, buyers, and fabricators is:

Should I use Hot Rolled Bars (HR) or Cold Drawn Bars (CD)?

Both are made from steel but undergo different manufacturing processes, which drastically change their:

- Surface finish

- Strength

- Tolerance

- Straightness

- Cost

- Applications

This guide breaks everything down in simple, buyer-friendly language.