If you work in fabrication, construction, automotive, appliances, engineering, or metal trading, you’ve definitely heard these two terms:

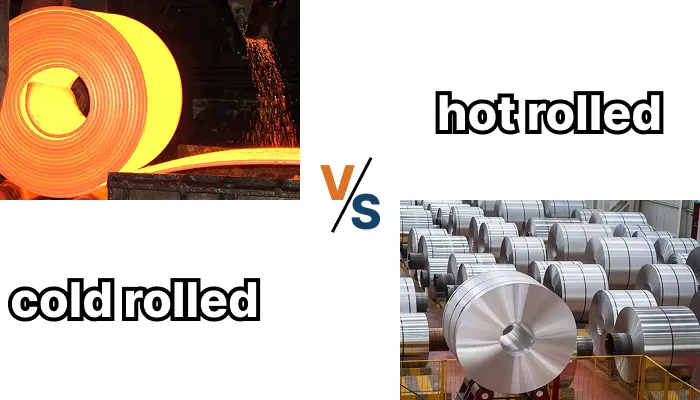

- 👉 Hot Rolled Steel (HR)

- 👉 Cold Rolled Steel (CR)

People often get confused about:

- Which one is stronger?

- Which one has better finish?

- Which one is cost-effective?

- Where should each be used?

This blog explains all differences in simple English, with real industry examples.