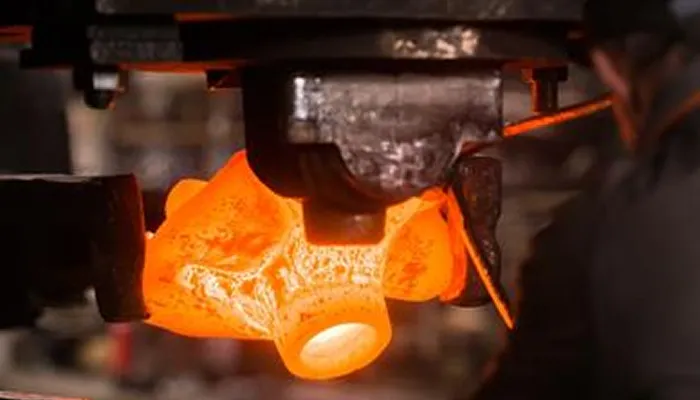

When it comes to materials that survive intense heat, pressure, corrosion, stress, oxidation, and mechanical load, few alloys even come close to the performance of Inconel. These nickel-chromium superalloys are built to perform in environments where stainless steel, duplex steel, and even exotic alloys fail prematurely.

From jet engines to offshore drilling tools, from chemical reactors to nuclear plants, Inconel alloys remain the gold standard for extreme environments.

At Moksh Tubes & Fittings LLP, we supply Inconel 600, 625, 718, 800, and 825 across global industries that depend on reliable high-temperature materials. This guide explains how Inconel behaves under extreme heat and pressure and why it is trusted worldwide.