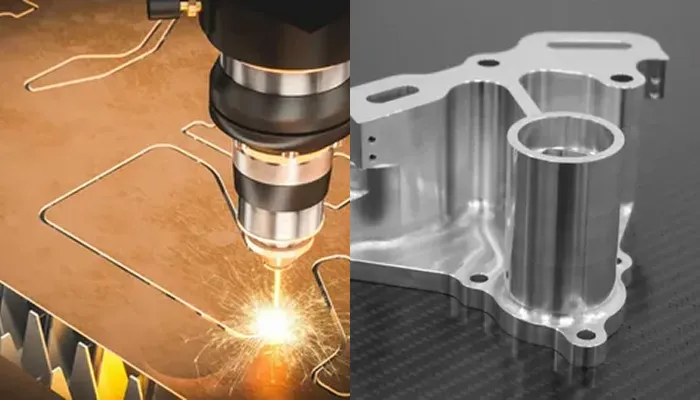

In modern metal fabrication, two technologies dominate:

- Laser Cutting

- CNC Machining

Both are used to manufacture precision-engineered components in industries like:

- Oil & Gas

- Chemical Plants

- Aerospace

- Automobiles

- Fabrication

- Machinery

- Defence

But businesses often struggle to choose:

- 👉 Which one gives better accuracy?

- 👉 Which process is more cost-effective?

- 👉 When should I use CNC machining instead of laser cutting?

- 👉 Which process works for thicker materials?

This guide gives a complete, human-friendly comparison between laser cutting and CNC machining, helping you make the right choice for your project.