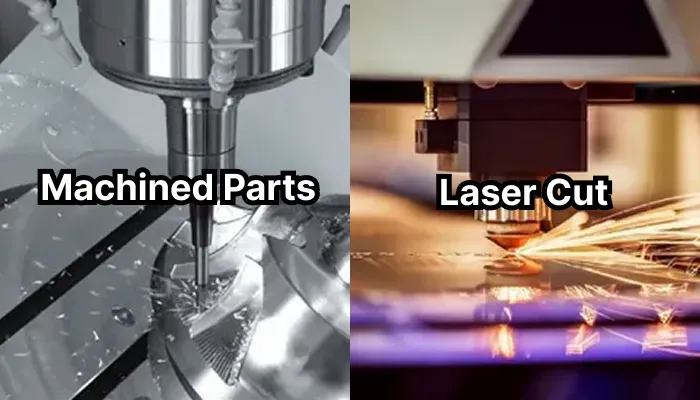

In modern metal fabrication, two technologies dominate: Laser Cutting and CNC Machining. Both are used to manufacture precision components across oil & gas, chemical plants, aerospace, automobiles, fabrication, machinery, and defence.

But many businesses struggle to choose between the two. This guide gives a clear, simple comparison to help you select the right process.