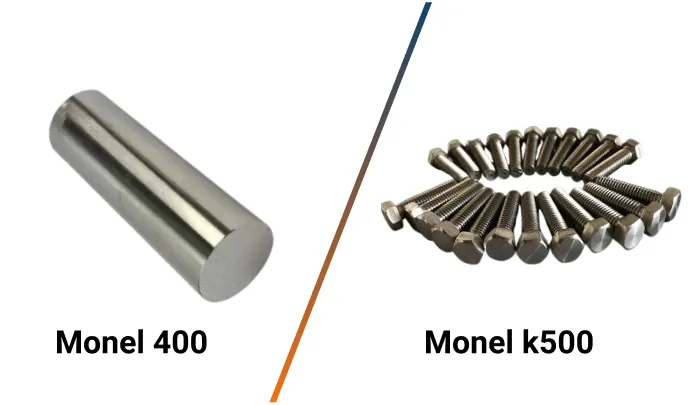

Monel alloys, especially Monel 400 and Monel K500, are widely used in the marine, offshore, petrochemical, and chemical industries because of their exceptional corrosion resistance and mechanical strength. But have you ever wondered how Monel pipes and tubes are manufactured with such precision, purity, and performance?

At Moksh Tubes & Fittings LLP, we specialize in supplying high-quality Monel seamless and welded pipes/tubes that meet strict ASTM, ASME, and international standards. Our customers, ranging from EPC contractors to marine engineering companies, depend on the quality of our products.