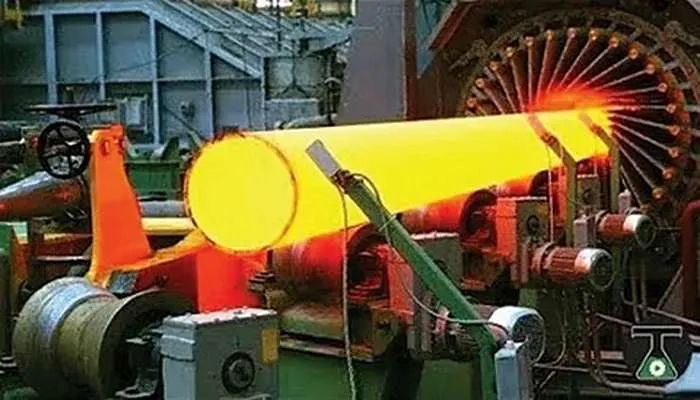

Seamless tubes are the backbone of high-pressure, high-temperature applications in boilers, heat exchangers, chemical plants, oil & gas pipelines, refineries, power plants, and automotive hydraulics.

They are known for:

- No weld

- No weak point

- High strength

- High pressure resistance

Yet most people don’t know how seamless tubes are manufactured. This guide explains the complete step-by-step process in simple English.