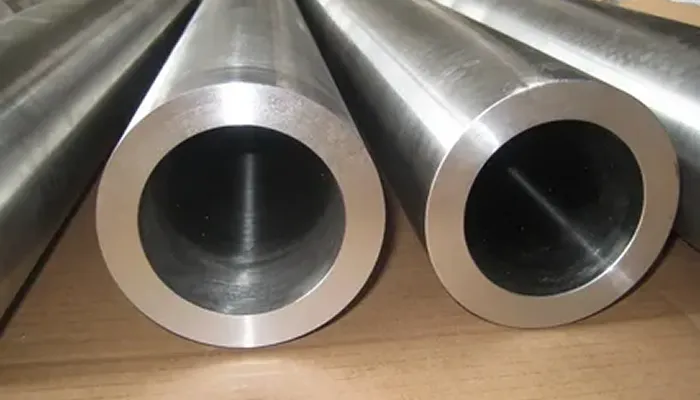

If there is one alloy that repeatedly proves its strength in the toughest industrial environments — it is Hastelloy C276. Known globally as the “universal corrosion-resistant alloy,” C276 continues to be the first choice for engineers, plant designers, EPC companies, and maintenance teams in industries where failure is not an option. From chemical processing plants to offshore oil rigs, fertilizer units, pollution control systems, and wastewater treatment facilities — Hastelloy C276 provides unmatched resistance to corrosion, high temperature, chlorides, oxidizers, and mixed chemicals. In this guide, we’ll explore the top 10 industrial applications of Hastelloy C276, backed by engineering logic, humanized explanations, real-world examples, and why this alloy continues to dominate in 2025.

Welcome to Moksh Tubes & Fittings LLP

Monday - Friday : 8:00 AM to 7:00 PM

-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Top 10 Industrial Applications of Hastelloy C276 – Why Engineers Prefer It

Top 10 Industrial Applications of Hastelloy C276 – Why Engineers Prefer It

What Makes Hastelloy C276 So Suitable for Industry?

Before diving into applications, it’s important to understand why industries trust this alloy more than any other.

Hastelloy C276 offers:

- ✔ Outstanding resistance to localised corrosion

- ✔ Stability in strong acids

- ✔ Resistance to chlorides (the biggest cause of stainless-steel failures)

- ✔ No sensitivity in weld zones

- ✔ Excellent high-temperature strength

- ✔ Resistance to mixed oxidizing + reducing chemicals

- ✔ Stellar performance in seawater

- ✔ Long service life → Lower downtime

These qualities make it almost irreplaceable in many critical industries.

Top 10 Applications of Hastelloy C276 (With Humanized Engineering Insight)

Let’s explore where and why industries prefer this alloy.

1. Chemical Processing Plants

Chemical plants are one of the harshest environments for any metal. Process streams include:

- Hydrochloric acid (HCl)

- Sulfuric acid

- Nitric acid mixtures

- Chlorides

- Organic acids

- Contaminated media

- High-temperature fluids

Most materials fail rapidly — but C276 has proven to survive for years without degradation.

Common C276 components:

- Reactors

- Heat exchangers

- Transfer piping

- Distillation units

- Columns and scrubbers

- Storage tanks

Reason: C276 resists almost every form of industrial corrosion.

2. Petrochemical & Refinery Industry

Refineries face extreme corrosion due to:

- Hydrogen sulfide (H₂S)

- Chlorides in crude oil

- Organic acids

- Wet sulphur compounds

- High temperatures

C276 remains stable even when exposed to contaminated feedstock.

Used in:

- Desulfurization units

- Strippers & contact towers

- Sour water treatment systems

- Furnace tubes

- Gas processing equipment

Refineries choose C276 because downtime = millions in losses.

3. Oil & Gas Industry (Onshore + Offshore)

The oil & gas industry deals with high pressures, sour gases, chlorides, seawater, and unpredictable chemistry.

C276 is used in:

- Downhole tubing

- Subsea pipelines

- Chemical injection systems

- Offshore platforms

- Wellhead components

316L, Duplex, and even Super Duplex often pit badly under seawater + pressure + chlorides. C276 handles all three effortlessly.

4. Marine & Seawater Applications

- Seawater cooling systems

- Offshore risers

- Pump shafts

- Water scrubbers

- Desalination plants

316L fails in 3–6 months in warm seawater. C276 lasts years with minimal maintenance.

5. Flue Gas Desulfurization (FGD) Systems

- Absorber towers

- Ducting

- Gas scrubbers

- Waste fluid disposal systems

6. Pharmaceutical & API Manufacturing

- Process vessels

- Heating coils

- Acid storage tanks

- Reaction systems

7. Pulp & Paper Industry

- Bleaching towers

- Digester systems

- Liquor tanks

- Recovery boilers

8. Mining & Metallurgy

- Leaching tanks

- Acid piping

- Autoclaves

- Extraction vessels

9. Wastewater Treatment Plants

- Filtration systems

- Aeration tanks

- Sludge digesters

- Chemical feed lines

10. Fertilizer & Agro-Chemical Plants

- Evaporators

- Compressors

- Reboilers

- Distribution headers

- Acid mixing & transfer lines

Additional Applications of Hastelloy C276

- Power generation units

- Heat recovery systems

- Pressure vessels

- Nuclear applications

- Urea production

- Textile factories

- Specialty chemical manufacturing

- Hydrogen production

Why Engineers Prefer Hastelloy C276 Over Other Alloys

It handles the broadest range of chemicals.

It tolerates high temperatures.

It doesn’t lose corrosion resistance at welds.

It lasts significantly longer.

It is backed by decades of proven performance.

Conclusion

Hastelloy C276 is not just an alloy — it is a guarantee of long-term reliability, especially in environments where corrosion is severe, chemical exposure is extreme, and equipment failure is unacceptable. Its performance across industries like chemical processing, oil & gas, marine, pollution control, and mining makes it a top choice for engineers worldwide. If your operations demand safety, efficiency, and minimal downtime, Hastelloy C276 is the smartest investment.

FAQ's

Why is C276 more expensive than stainless steel?

Because it contains high nickel, molybdenum, and chromium — premium corrosion-resistant metals.

Is C276 suitable for seawater?

Yes, it is one of the best alloys for long-term seawater performance.

Can C276 be used in high-temperature acidic environments?

Absolutely. It is designed for such extreme conditions.

Where should you NOT use C276?

Applications above 1100°C or where corrosion is very mild (316L is cheaper).

Recent Blogs

-

Why Nickel Alloy Bars Are Used in High-Temperature Industries

December 11, 2025

Locate Us

info@mokstubes.com

Office Address: Hinglaj Bhavan, Gulalwadi Mumbai, Maharashtra. 400004

Office Address: 6/A, Ground Floor, Rajwanti Mansion, Khetwadi Mumbai

Office Address: 95/95A, Dawood Baug, Sukhlaji Street, Kamatipura Mumbai

Office Address: 92E, Plot No. 3, New Tank Bunder, Darukhana, Mumbai, Maharashtra- 400 010.

get in touch

Let’s forge a connection — contact our team today.

Contact Us

At Moksh Tubes & Fittings LLP, we’re dedicated to making your purchases seamless — offering expert advice, a wide inventory of certified products, and global support for every order, large or small.

Get in TouchGet in Touch

We use cookies to personalize content, improve site performance, and analyze traffic. Some cookies are essential for the site to function correctly. You can manage your preferences or accept all cookies.