Engineering steels—also known as specialty carbon and alloy steels—form the backbone of modern manufacturing. From automotive components to heavy machinery, oil & gas tools, shafts, gears, valves, and precision components, engineering steels are designed for strength, hardness, shock resistance, and fatigue performance.

In 2025, industries demand:

- Higher load-bearing performance

- Better wear resistance

- High toughness under stress

- Ability to withstand impact & torsion

- Dimensional stability after machining

- Long-term reliability

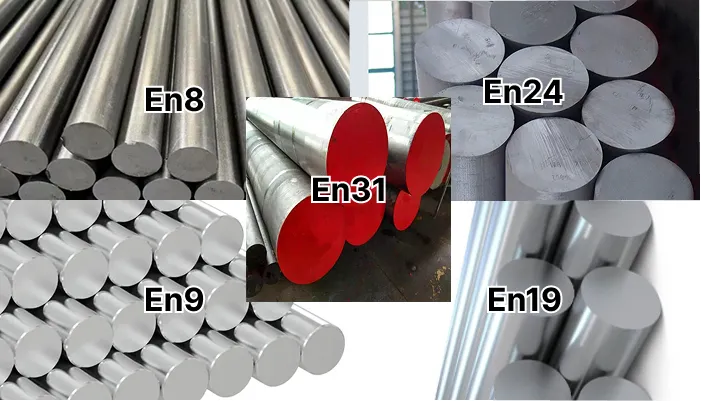

Grades like EN8, EN9, EN19, EN24, and EN31 have become extremely popular because they offer exceptional mechanical properties at competitive cost.

This complete guide breaks down what engineering steels are, how each grade performs, and which industries rely on them.