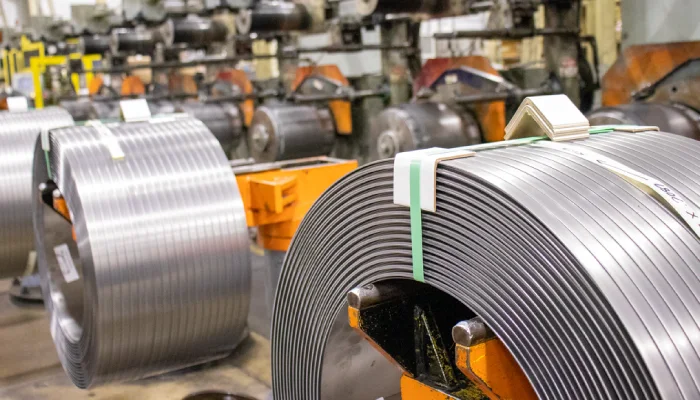

Metal coils are one of the most widely used raw materials in industries like Automotive, Construction, Appliances, Oil & Gas, Piping Systems, Manufacturing, HVAC, and Fabrication.

But many people still get confused about:

- 👉 What exactly is a metal coil?

- 👉 How is it made?

- 👉 Why do industries choose coils over sheets?

- 👉 What are the different types of coils?

- 👉 Which coil is best for which application?

This guide explains everything in simple, beginner-friendly English.