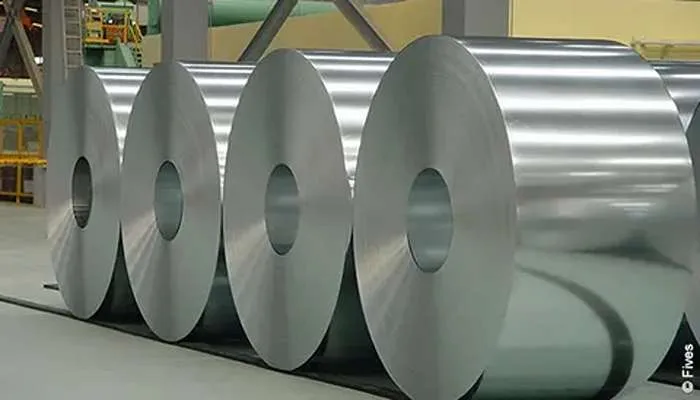

Metal coils are one of the most widely used raw materials in industries like automotive, construction, appliances, oil & gas, piping systems, manufacturing, HVAC, and fabrication.

But many people still get confused about what a metal coil is, how it is made, and where it should be used. This guide explains everything in simple, beginner-friendly English.