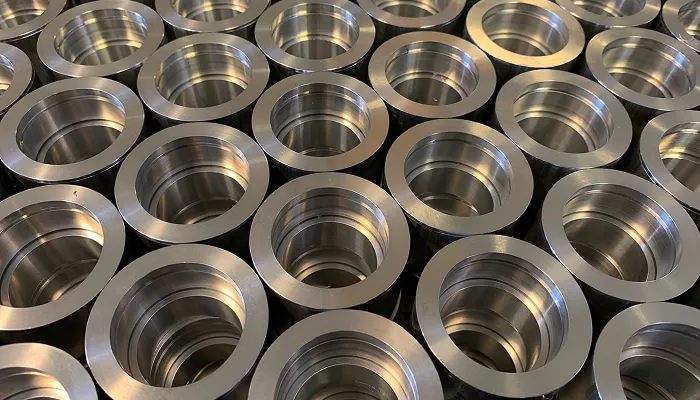

For decades, alloy steels such as EN19, EN24, 4140, 4340, and tool steels have dominated industries like aerospace, defence, and oil & gas. But 2025 marks a major shift.

Companies are rapidly replacing alloy steels with High Strength Stainless Steels (HSSS) such as:

- 17-4 PH (S17400)

- 15-5 PH (S15500)

- 13-8 MO (S13800)

- 440C stainless steel

- 431 stainless steel

- Super Duplex (2507)

High Strength Stainless Steels offer the perfect balance of strength + corrosion resistance + cost-effectiveness, making them the material of choice for 2025 and beyond.