-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Copper Alloys C44300 | Product Overview

Introduction To Beryllium Copper / UNS C17200 / ALLOY 25

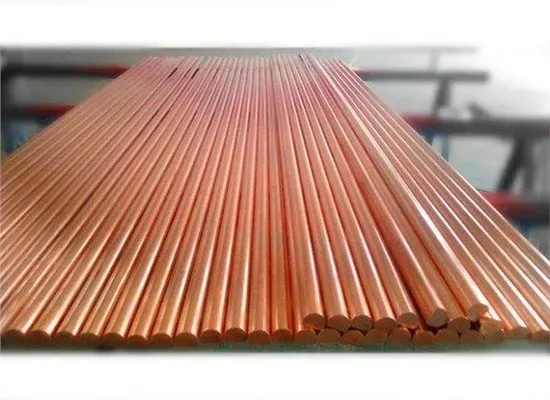

MOKSH TUBES & FITTINGS LLP is a reliable manufacturer, exporter, importer, and stockist of high-quality Beryllium Copper products. We offer a wide range of forms, including Pipes & Tubes, Sheets & Plates, Coils, Rods, Bars, Wire, Foil, Forgings, and Custom Components tailored to industrial needs.

Beryllium Copper, also known as Copper Beryllium, is a high-performance alloy known for its remarkable combination of strength, conductivity, and corrosion resistance. This non-ferrous alloy contains 0.4% to 2% beryllium and is often used where non-sparking, non-magnetic, and high-strength materials are required. It can be heat-treated for enhanced mechanical properties and performs excellently in electrical, aerospace, marine, and oil & gas environments.

Download Copper Alloys Beryllium Coppar Datasheet

Get the complete Copper Alloys Beryllium Coppar datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Chemical Composition of Beryllium Copper C17200

| Element | Composition (%) |

|---|---|

| Beryllium (Be) | 1.80 – 2.00 |

| Cobalt + Nickel (Co + Ni) | 0.20 – 0.50 |

| Copper (Cu) | Balance |

| Iron (Fe) | 0.15 max |

| Lead (Pb) | 0.02 max |

| Others (each) | 0.10 max |

Physical Properties of Beryllium Copper C17200

| Property | Value |

|---|---|

| Density | 8.25 g/cm³ |

| Melting Point | 866 – 982 °C |

| Electrical Conductivity | 20 – 65% IACS |

| Thermal Conductivity | 105 W/m·K |

| Specific Heat Capacity | 0.38 J/g·K |

| Modulus of Elasticity | 131 GPa |

Heat Treatment of Beryllium Copper C17200

| Heat Treatment Stage | Temperature Range | Purpose |

|---|---|---|

| Solution Annealing | 760 – 800°C | Dissolves beryllium into copper matrix |

| Quenching | Water quench | Retains solid solution |

| Age Hardening (Precipitation) | 315 – 325°C (2–3 hrs) | Achieves maximum strength & hardness |

| Stress Relieving | 260 – 315°C | Reduces internal stresses |

📌 After precipitation hardening, C17200 can reach up to 45 HRC with excellent fatigue resistance.

Mechanical Properties of Beryllium Copper C17200 (Aged)

| Property | Annealed (TB00) | Cold-Drawn | Precipitation Hardened (HT) |

|---|---|---|---|

| Tensile Strength | 415–585 MPa | 620–1140 MPa | 1140–1585 MPa |

| Yield Strength (0.2%) | 275–345 MPa | ≈90% of TS | ≈90% of TS |

| Elongation | 20–30% | 10–20% | 2–5% |

| Hardness | 35–60 HRB | Up to 60 HRB | 36–45 HRC |

| Electrical Conductivity | 19–28% IACS | 15–20% IACS | 15–20% IACS |

Available Forms & Size Range – Beryllium Copper C17200

| Product Form | Size Range |

|---|---|

| Sheets & Plates | 0.5 – 50 mm |

| Coils & Strips | 0.1 – 5 mm |

| Rods & Bars | Ø 5 – 300 mm |

| Pipes & Tubes | OD 6 – 150 mm |

| Wires & Foils | As thin as 0.02 mm |

| Forged Components | As per drawing |

International Standards & Equivalent Grades – C17200

| Standard | Equivalent |

|---|---|

| UNS | C17200 |

| ASTM | Alloy 25 |

| SAE | J461 / J463 |

| AMS | 4533, 4534, 4535, 4650 |

| DIN | CuBe2 |

| ISO | CuBe2 |

Products in Beryllium Copper

Beryllium Copper is available in:

Beryllium Copper products are produced to the following global standards:

Uses and Advantages

High strength comparable to steels

Excellent fatigue and stress relaxation resistance

Non-magnetic and non-sparking

High electrical and thermal conductivity

Excellent corrosion and wear resistance

Applications of Beryllium Copper

Beryllium Copper is widely chosen for its unmatched combination of high strength, corrosion resistance, and non-magnetic properties, making it indispensable in:

Electrical & Electronics

Connectors, contacts, switches, relays, springs, EMI shielding

Aerospace & Defense

Aircraft bushings, landing gear components, missile parts

Oil & Gas Industry

Non-sparking tools, downhole components, wellhead parts

Marine Engineering

Valve parts, pump shafts, corrosion-resistant hardware

Automotive Industry

ABS brake components, engine contacts, sensor springs

Tooling & Molds

Injection molds, die-casting inserts, electrodes for EDM

WHY CHOOSE US?

BERYLLIUM COPPER PRICE PER KG (INDIA)

Typical Range: ₹4,500 – ₹9,000 per kg

(Price varies by OD, wall thickness, form, and finish)

Contact us for exact quotation based on size and quantity.

FAQ's

What is Beryllium Copper and what are its key properties?

Beryllium Copper (CuBe) is a high-performance copper alloy containing 0.4%–2% beryllium. It is valued for its exceptional strength, electrical and thermal conductivity, non magnetic behavior, and corrosion resistance. It can be heat treated for even higher mechanical strength, making it ideal for demanding applications.

What are the main applications of Beryllium Copper?

Beryllium Copper is widely used in electrical & electronics, aerospace & defense, marine engineering, oil & gas, automotive, and tooling industries. Common applications include connectors, contacts, springs, non-sparking tools, valve components, bearings, molds, and aerospace hardware.

Why is Beryllium Copper preferred over other copper alloys?

Unlike standard copper alloys, Beryllium Copper provides a unique balance of high strength and conductivity. It offers better fatigue resistance, non-sparking safety, and non-magnetic properties, making it superior in critical environments like offshore platforms, defense systems, and high precision electrical components.

What Beryllium Copper products does MOKSH TUBES & FITTINGS LLP supply?

We manufacture and stock a wide range of Beryllium Copper products, including pipes, tubes, sheets, plates, coils, bars, wires, foils, forgings, pipe fittings, flanges, fasteners, and custom fabricated components, all produced to international standards such as ASTM, AMS, and DIN.

Why choose MOKSH TUBES & FITTINGS LLP for Beryllium Copper materials?

MOKSH TUBES & FITTINGS LLP is a trusted global supplier offering strict quality control, custom sizes, fast delivery, and compliance with international standards. With our technical expertise, global logistics, and reliable material traceability, we are the preferred choice for high quality Beryllium Copper solutions.

blogs

Why Copper Alloys Matter: Prop...

Copper is one of the oldest and most versatile metals known to humanity — yet in 2025, it remains one...

Beryllium Copper (BeCu) — Stro...

Beryllium Copper (BeCu) is one of the highest performance copper alloys ever developed. It uniquely comb...

Copper-Nickel 90/10 vs 70/30 –...

Copper-Nickel alloys (Cu-Ni) are among the world’s best materials for seawater corrosion...Contact Us

contact Moksh Tubes & Fittings LLP — for reliable supply, precision quality, and unbeatable service. Get in Touch