-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction To Tantalum

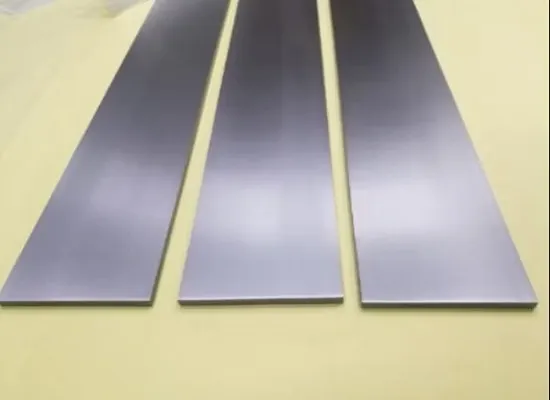

MOKSH TUBES & FITTINGS LLP is a reliable manufacturer, supplier, exporter, importer, and stockist of premium-grade Tantalum products including Tantalum Pipes & Tubes, Sheets & Plates, Rods & Bars, Wire, Foil, Crucibles, Fasteners, and Custom Fabricated Products for critical applications.

Tantalum is a rare, ductile, and highly corrosion-resistant metal with excellent biocompatibility and high melting point. It is highly resistant to most acids (including aqua regia), making it a prime material for demanding chemical processing and high-temperature applications. Tantalum maintains its mechanical strength at elevated temperatures and offers excellent workability in various forms.

Download Hard To Find Special Alloy Tantalum Datasheet

Get the complete Hard To Find Special Alloy Tantalum datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – Tantalum (Ta)

| Property | Details |

|---|---|

| Material | Tantalum (Ta) |

| Atomic Number | 73 |

| Purity | ≥ 99.95% |

| Density | 16.69 g/cm³ |

| Melting Point | 2996 °C |

| Corrosion Resistance | Excellent (including aqua regia) |

| Biocompatibility | Excellent |

| Magnetic Property | Non-Magnetic |

| Thermal Stability | Excellent |

| Workability | Good (annealed condition) |

Chemical Composition of Tantalum (99.95% min)

| Element | Composition (%) |

|---|---|

| Tantalum (Ta) | 99.95 min |

| Niobium (Nb) | 0.01 – 0.10 max |

| Iron (Fe) | 0.01 max |

| Titanium (Ti) | 0.01 max |

| Tungsten (W) | 0.05 max |

| Silicon (Si) | 0.005 max |

| Oxygen (O) | 0.015 max |

| Nitrogen (N) | 0.01 max |

| Carbon (C) | 0.01 max |

| Hydrogen (H) | 0.001 max |

Physical Properties of Tantalum

| Property | Imperial Units | Metric Units |

|---|---|---|

| Density | 0.311 lb/in³ | 16.69 g/cm³ |

| Melting Point | 5425 °F | 2996 °C |

| Elastic Modulus (Tension) | 15 × 10³ ksi | 103 GPa |

| Elastic Modulus (Compression) | 15 × 10³ ksi | 103 GPa |

| Elastic Modulus (Torsion) | 6 × 10³ ksi | 41 GPa |

| Poisson’s Ratio | 0.34 | — |

| Curie Temperature | Not applicable | Not applicable |

Heat Treatment & Fabrication of Tantalum

| Process | Temperature Range | Purpose |

|---|---|---|

| Annealing | 900 – 1200 °C | Restore ductility |

| Stress Relieving | 600 – 800 °C | Reduce residual stress |

| Cold Working | — | Increase strength |

| Welding | — | TIG / EB welding preferred |

| Machining | — | Carbide tools recommended |

✔ Tantalum cannot be hardened by heat treatment; properties are controlled via cold work and annealing.

Mechanical Properties of Tantalum (Annealed)

| Property | Annealed | Cold-Drawn | Sheet |

|---|---|---|---|

| Tensile Strength | 276 – 414 MPa | 517 – 690 MPa | 276 – 414 MPa |

| Yield Strength (0.2%) | 138 – 276 MPa | 345 – 552 MPa | 172 – 310 MPa |

| Elongation | 30 – 50% | 10 – 25% | 30 – 50% |

| Brinell Hardness | 90 – 120 | 140 – 180 | 90 – 120 |

| Rockwell Hardness | 40 – 50 B | 60 – 70 B | 40 – 50 B |

Available Forms & Size Range – Tantalum

| Product Form | Size Range |

|---|---|

| Rods & Bars | Ø 2 – 150 mm |

| Sheets & Plates | 0.05 – 40 mm |

| Foils | As thin as 0.01 mm |

| Pipes & Tubes | OD 6 – 120 mm |

| Wires | 0.02 – 5 mm |

| Crucibles | Standard & custom |

| Machined Parts | As per drawing |

International Standards & Equivalent Grades – Tantalum

| Standard | Equivalent Grade |

|---|---|

| ASTM | B365, B521, B708, B775 |

| UNS | R05200, R05400 |

| DIN | 3.7103 |

| AMS | AMS 7850 |

| ASTM Medical | ASTM F560 |

| ISO | ISO 9001 |

Products in Tantalum

Tantalum is commonly supplied as:

We supply Tantalum materials in accordance with the most stringent industry standards:

Uses and Advantages

Excellent corrosion resistance to almost all acids including aqua regia

High melting point (over 3000°C)

Exceptional biocompatibility for medical applications

Outstanding thermal and electrical conductivity

Non-toxic and suitable for ultra-pure environments

Applications of Tantalum

Chemical Processing Equipment

Used in heat exchangers, reactors, vessels, and piping systems where resistance to strong acids like HCl, H2SO4, and nitric acid is critical.

Electronics & Semiconductors

Employed in sputtering targets, capacitors, and thin-film applications due to high capacitance and purity.

Medical Industry

Used for surgical implants, orthopedic devices, and dental applications owing to its excellent biocompatibility and non-reactive nature.

Aerospace and Defense

Utilized in high-temperature structural parts and radiation shielding components.

Laboratory Equipment

Ideal for crucibles, evaporation boats, and heat-resistant components in vacuum systems.

WHY CHOOSE US?

TANTALUM PRICE PER KG (INDIA)

Typical Range: ₹18,000 – ₹45,000 per kg

(Price varies by OD, wall thickness, form, and finish)

Contact us for exact quotation based on size and quantity.

FAQ's

What is Tantalum and where is it used?

Tantalum is a highly corrosion-resistant metal with a high melting point, used in chemical processing, electronics, medical implants, aerospace, and laboratory equipment for its durability, biocompatibility, and resistance to strong acids.

Which forms of Tantalum products are available?

Tantalum is supplied as seamless and welded pipes, tubes, sheets, plates, coils, strips, round/flat/hex/square bars, pipe fittings, flanges, fasteners, wire, foil, crucibles, and custom-fabricated components.

What are the key advantages of Tantalum?

Tantalum offers excellent corrosion resistance to acids, high thermal and electrical conductivity, exceptional biocompatibility, non toxicity, and suitability for ultra-pure environments, while maintaining strength at high temperatures.

In which industries is Tantalum commonly applied?

Tantalum is widely used in chemical processing equipment, electronics and semiconductor components, medical devices, aerospace and defense, and laboratory equipment due to its chemical and thermal stability.

Why choose MOKSH TUBES & FITTINGS for Tantalum alloys?

We provide high-purity Tantalum in various grades, precision manufacturing, in-house quality testing, fast turnaround, custom solutions, global logistics, and reliable documentation, trusted by chemical, aerospace, and electronics industries worldwide.

blogs

2025 Special Alloy Buyer’s Gui...

Choosing the right material is one of the most critical decisions in engineering. A wrong all...

Aerospace-Grade Alloys: Why Ti...

Aerospace engineering demands the most advanced and reliable alloys ever created. Aircraft, rockets, and turbine...

Why MP35N, Hastelloy C276 & Zi...

Not all engineering environments are equal. Some industries operate in conditions so harsh that stainl...Contact Us

Contact Moksh Tubes & Fittings LLP — for quotes, technical queries, and bulk orders. We are your one-stop solution for rare metals and corrosion-resistant alloys.

Get in Touch