-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

INTRODUCTION TO 15-5 PH STAINLESS STEEL / UNS S15500 / ASTM A564

MOKSH TUBES & FITTINGS LLP is a trusted supplier, exporter, importer, and stockist of high-quality 15-5 PH Stainless Steel products, including Pipes & Tubes, Pipe Fittings, Flanges, Fasteners, Sheets & Plates, Coils, Wires, Round Bars, Flat Bars, Angles, Channels, Welding Rods, Wire Mesh, and Custom Fabricated Components.

15-5 PH (Precipitation Hardening) Stainless Steel, designated as UNS S15500, is a martensitic chromium–nickel–copper stainless steel designed for high strength, excellent corrosion resistance, and superior toughness. Developed as an improvement over 17-4 PH, this alloy offers enhanced transverse toughness and more uniform mechanical properties than traditional precipitation-hardening grades.

The alloy can be hardened through a simple low-temperature aging process without distortion or scaling, allowing engineers to achieve the required strength levels efficiently. With its balance of strength, ductility, and corrosion resistance, 15-5 PH Stainless Steel remains a versatile solution for both structural and critical component applications.

Download High Strength Stainless Steel 15-5ph Datasheet

Get the complete High Strength Stainless Steel 15-5ph datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – 15-5 PH Stainless Steel (UNS S15500)

| Property | Details |

|---|---|

| Material Type | Precipitation Hardening Martensitic Stainless Steel |

| UNS Designation | S15500 |

| ASTM / AMS | ASTM A564 / AMS 5659 |

| Strengthening Method | Solution Anneal + Aging |

| Heat Treatable | ✔ Yes |

| Typical Hardness Range | 28 – 44 HRC (condition dependent) |

| Corrosion Resistance | Better than 17-4 PH |

| Toughness | Excellent (Superior transverse properties) |

| Magnetic Property | Fully Magnetic |

| Typical Density | ~7.78 g/cm³ |

📌 15-5 PH is preferred over 17-4 PH where higher toughness, uniformity, and aerospace reliability are required.

Chemical Composition of 15-5 PH Stainless Steel

| Element | Composition (%) |

|---|---|

| Chromium (Cr) | 14.00 – 15.50 |

| Nickel (Ni) | 3.50 – 5.50 |

| Copper (Cu) | 2.50 – 4.50 |

| Manganese (Mn) | 1.00 max |

| Silicon (Si) | 1.00 max |

| Columbium + Tantalum (Cb + Ta) | 0.15 – 0.45 |

| Carbon (C) | 0.07 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.030 max |

| Iron (Fe) | Balance |

Technical Composition of 15-5 PH Stainless Steel

Physical Properties of 15-5 PH Stainless Steel

| Property | Value |

|---|---|

| Density | 7.78 g/cm³ |

| Melting Point | 1400–1450 °C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 18.4 W/m·K at 100 °C |

| Specific Heat | 460 J/kg·K |

| Electrical Resistivity | 0.80 µΩ·m |

Heat Treatment & Aging Conditions – 15-5 PH

| Condition | Aging Temp | Key Characteristics |

|---|---|---|

| Condition A | 1040°C + Air Cool | Soft, machinable |

| H900 | 482°C | Maximum strength |

| H1025 | 552°C | Best balance of strength & toughness |

| H1075 | 580°C | Improved ductility |

| H1150 | 620°C | Maximum toughness & SCC resistance |

| H1150M | Double aged | Marine & aerospace critical use |

📌 Lower aging temperature = higher strength

📌 Higher aging temperature = higher toughness & corrosion resistance

Mechanical Properties of 15-5 PH (H1025 Condition)

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 1170 MPa | 170,000 psi |

| Yield Strength (0.2%) | 1070 MPa | 155,000 psi |

| Elongation | 12–15 % | 12–15 % |

| Reduction of Area | 45 % | 45 % |

| Hardness | 38–44 HRC | 38–44 HRC |

| Impact Toughness | Excellent transverse & longitudinal toughness | |

Note: Properties vary depending on heat treatment condition (H900, H1025, H1150).

International Standards & Equivalent Grades – 15-5 PH

| Standard | Equivalent |

|---|---|

| UNS | S15500 |

| ASTM | A564, A693 |

| AMS | 5659, 5862 |

| EN | 1.4545 |

| DIN | X5CrNiCuNb15-5 |

| JIS | SUS 630 (closest) |

| ISO | X5CrNiCuNb15-5 |

Products in 15-5 PH Stainless Steel

MOKSH TUBES & FITTINGS LLP, with deep expertise in high-performance stainless steels and an extensive global sourcing network, offers a comprehensive range of 15-5 PH Stainless Steel products. These products are ideally suited for applications requiring high strength, corrosion resistance, and reliability in demanding sectors such as Aerospace, Petrochemical, Power Generation, and Marine Industries.

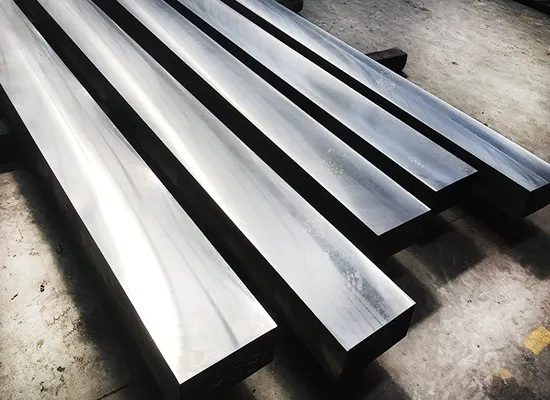

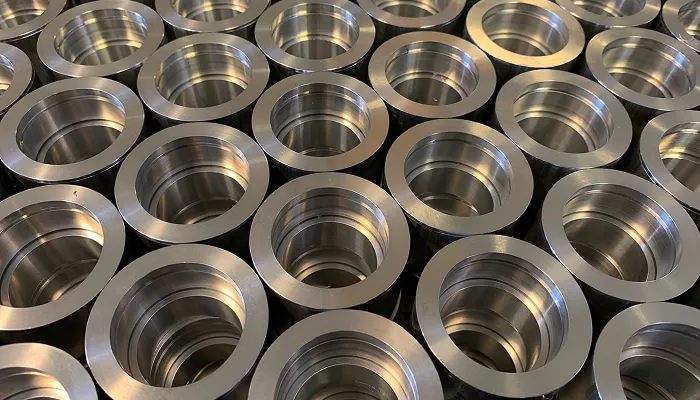

We offer 15-5 PH Stainless Steel in a wide range of product forms to meet industrial demands.

Uses and Advantages of 15-5PH stainless steel

High Strength & Toughness

Provides exceptional mechanical properties even at elevated temperatures.

Excellent Corrosion Resistance

Resists atmospheric corrosion, fresh water, mild acids, and industrial environments.

Good Fabrication Characteristics

Easily machined, welded, and formed with minimal distortion during heat treatment.

Stable Properties Through Heat Treatment

Simple aging treatment achieves high strength without complex processes.

Superior Transverse Properties

Offers more uniform and reliable performance compared to older PH grades like 17-4 PH.

Versatile Applications

Ideal for structural, high-pressure, and precision-engineered components.

Applications of 15-5 PH Stainless Steel

15-5 PH Stainless Steel is widely used in critical engineering sectors that demand high strength, durability, and corrosion resistance. Below are some key application areas:

Aerospace Industry

Aircraft fittings, landing gear components, shafts, and structural elements requiring light weight and high strength.

Chemical & Petrochemical Processing

Shafts, valves, pump parts, and fittings exposed to mildly corrosive and high-pressure environments.

Power Generation

Steam turbine components, high-strength bolting, and critical rotating parts.

Marine & Offshore Engineering

Propeller shafts, drive shafts, structural components, and fasteners resistant to seawater and brackish environments.

Pulp & Paper Industry

Equipment that requires resistance to moisture, mild chemicals, and mechanical wear.

Food & Pharmaceutical Equipment

Components requiring a balance of hygiene, corrosion resistance, and mechanical strength.

General Engineering & Tooling

Gears, molds, dies, and precision tools that benefit from high hardness and excellent machinability.

WHY CHOOSE US?

15-5 PH Stainless Steel Price per kg in India

Typical Range: ₹560 – ₹1,300 per kg

(Price varies by OD, wall thickness, form, and finish)

Contact us for exact quotation based on size and quantity.

FAQ's – 15-5 PH Stainless Steel

What is 15-5 PH Stainless Steel?

15-5 PH Stainless Steel is a high-strength, corrosion-resistant alloy used in aerospace, marine, and chemical industries for demanding applications.

What are its main properties?

It offers high strength, excellent corrosion resistance, good toughness, and the ability to achieve heat-treatable hardness.

Where is it used?

Common applications include aerospace components, chemical processing equipment, marine shafts, pump components, and medical devices.

Is it weldable?

Yes, it can be welded using proper techniques such as TIG or MIG. Post-weld heat treatment is recommended to maintain optimal properties.

Why choose MOKSH TUBES & FITTINGS LLP for 15-5 PH Stainless Steel?

MOKSH TUBES & FITTINGS LLP offers premium-grade 15-5 PH stainless steel with guaranteed quality, global delivery capability, and competitive pricing, making us a trusted partner for critical applications worldwide.

blogs

Why High Strength Stainless St...

For decades, alloy steels such as EN19, EN24, 4140, 4340, and tool steels have dominated industries like aerospace...

High Strength Stainless Steel...

Choosing the right engineering material in 2025 is more complex than ever. Industries such as oil & gas, aeros...

Top Industrial Applications of...

High Strength Stainless Steels (HSSS) such as 17-4 PH, 15-5 PH, 13-8 MO, 440C, 431, and Super Duplex 2...Contact Us

For any inquiries or to request a quote, get in touch with Moksh Tubes & Fittings LLP – your reliable partner for 15-5 PH Stainless Steel products and solutions.

Get in Touch