-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

INTRODUCTION TO 430F STAINLESS STEEL / AISI 430F / UNS S43020

MOKSH TUBES & FITTINGS LLP is a leading supplier, exporter, importer, and stockist of a wide variety of 430F Stainless Steel products including Pipes & Tubes, Pipe Fittings, Flanges, Fasteners, Sheets & Plates, Coils, Wires, Round Bars, Flat Bars, Angles, Channels, Wire Mesh, and other custom and hard-to-find 430F products.

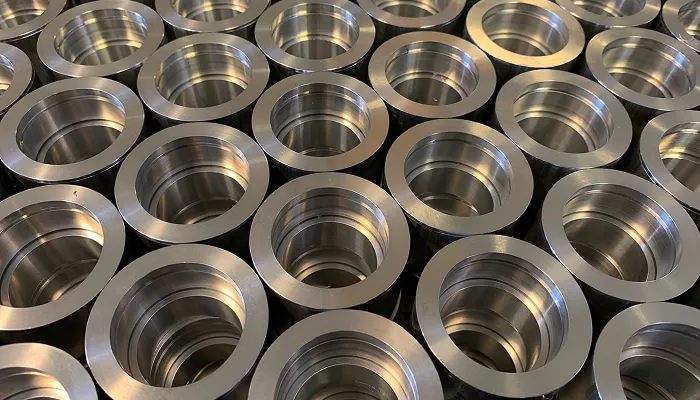

430F Stainless Steel is a free-machining ferritic stainless steel, specifically modified with controlled amounts of sulfur to enhance machinability. This improvement makes it highly suitable for automatic screw machining, high-speed manufacturing, and precision-engineered components where quick production turnaround is essential.

The alloy offers good resistance to oxidation, moderate corrosion resistance in various environments, and excellent magnetic properties. Its performance is reliable in applications where aesthetics, dimensional accuracy, and medium corrosion protection are required.

Unlike austenitic stainless grades, 430F cannot be hardened through heat treatment but gains strength via cold working processes. Its ferritic microstructure ensures solid dimensional stability and ease of fabrication, positioning it as a cost-effective alternative for non-critical corrosion-resistant applications.

Download High Strength Stainless Steel 430F Datasheet

Get the complete High Strength Stainless Steel 430F datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – SS 430F / UNS S43020

| Property | Details |

|---|---|

| Material Type | Ferritic Stainless Steel (Free-Machining) |

| UNS Designation | S43020 |

| AISI | 430F |

| Chromium Content | 16.0 – 18.0 % |

| Sulfur Content | 0.15 – 0.35 % (for machinability) |

| Heat Treatable | ❌ No (Not hardenable) |

| Machinability | Excellent (Automatic screw machining) |

| Corrosion Resistance | Moderate |

| Oxidation Resistance | Good |

| Magnetic Property | Fully Magnetic |

| Typical Density | ~7.70 g/cm³ |

Chemical Composition of SS 430F

| Element | Composition (%) |

|---|---|

| Carbon (C) | ≤ 0.12 |

| Manganese (Mn) | ≤ 1.25 |

| Silicon (Si) | ≤ 1.00 |

| Phosphorus (P) | ≤ 0.06 |

| Sulfur (S) | 0.15 – 0.35 |

| Chromium (Cr) | 16.0 – 18.0 |

| Iron (Fe) | Balance |

👉 The sulfur addition significantly improves machinability, making 430F ideal for precision-turned and threaded components.

Technical Composition of SS 430F

Physical Properties of SS 430F

| Property | Value |

|---|---|

| Density | 7.70 g/cm³ |

| Melting Point | 1425 – 1510 °C |

| Modulus of Elasticity | ~200 GPa |

| Thermal Conductivity | 25 W/m·K (100 °C) |

| Electrical Resistivity | 0.60 µΩ·m |

| Magnetic Properties | Fully Magnetic (Ferritic) |

Heat Treatment of Stainless Steel 430F

| Process | Temperature Range | Purpose |

|---|---|---|

| Annealing | 760 – 815 °C | Restores ductility after cold work |

| Stress Relieving | 600 – 650 °C | Reduces machining stresses |

| Hardening | ❌ Not Applicable | Ferritic structure |

| Cold Working | — | Improves strength (limited) |

📌 SS 430F cannot be hardened by heat treatment. Strength improvements are achieved mainly through cold working.

Mechanical Properties of SS 430F

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 415 – 620 MPa | 60,000 – 90,000 psi |

| Yield Strength (0.2%) | ~275 MPa | 40,000 psi |

| Elongation | 20% | 20% |

| Hardness (Brinell) | 170 – 200 HB | 170 – 200 HB |

👉 SS 430F offers excellent machinability but lower ductility than austenitic stainless steels.

International Standards & Equivalent Grades – SS 430F

| Standard | Equivalent Grade |

|---|---|

| UNS | S43020 |

| AISI | 430F |

| EN | 1.4105 |

| DIN | X8CrS17 |

| ASTM | A276, A582 |

| JIS | SUS 430F |

| ISO | X8CrS17 |

Products in 430F Stainless Steel

MOKSH TUBES & FITTINGS LLP, leveraging its strong global supply network and expertise in ferritic stainless steels, offers a comprehensive range of 430F Stainless Steel products for multiple industrial sectors. Known for its excellent machinability and good corrosion resistance, 430F is ideal for automatic machining and high-volume production.

Our 430F Stainless Steel range is engineered to deliver consistent machining performance, durability, and corrosion resistance for various industrial applications.