-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction to Stainless Steel 405 / AISI 405 / UNS S40500

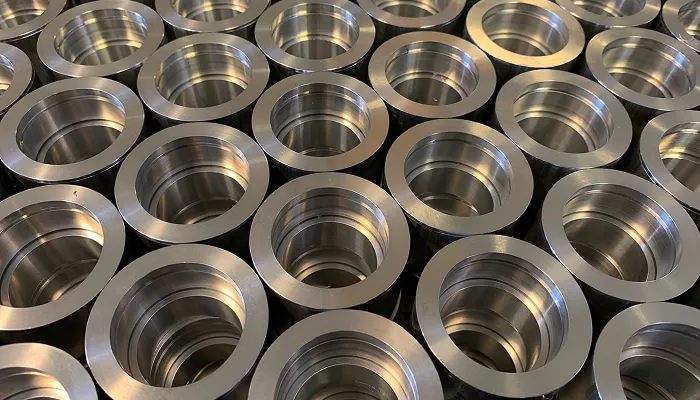

MOKSH TUBES & FITTINGS LLP is a trusted supplier, exporter, importer, and stockist of a comprehensive range of Stainless Steel 405 products, including Pipes & Tubes, Pipe Fittings, Flanges, Fasteners, Sheets & Plates, Coils, Wires, Round Bars, Flat Bars, Angles, Channels, Wire Mesh, and various custom or hard-to-find components.

Stainless Steel 405 is a 12% chromium ferritic stainless steel, specially designed to minimize hardening when cooled from high temperatures. The addition of aluminium (~0.10–0.30%) improves its oxidation resistance and prevents excessive hardening during welding, making it particularly useful for welded or fabricated applications where post-weld annealing is not practical.

This grade offers moderate corrosion resistance, good weldability, excellent scaling resistance, and is magnetic in all conditions. It’s frequently used in automotive exhaust systems, annealing boxes, steam nozzles, turbine blades, and structural components exposed to mild environments.

Download High Strength Stainless Steel 405 Datasheet

Get the complete High Strength Stainless Steel 405 datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – SS 405 / UNS S40500

| Property | Details |

|---|---|

| Material Type | Ferritic Stainless Steel |

| UNS Designation | S40500 |

| AISI | 405 |

| Chromium Content | 11.5 – 14.5 % |

| Alloying Addition | Aluminium (0.10 – 0.30%) |

| Heat Treatable | ❌ No (Not hardenable) |

| Oxidation Resistance | Excellent |

| Corrosion Resistance | Moderate |

| Magnetic Property | Fully Magnetic |

| Typical Density | ~7.75 g/cm³ |

👉 Aluminium addition improves oxidation resistance and prevents air-hardening during welding, making SS 405 ideal for welded and exhaust components.

Chemical Composition of Stainless Steel 405

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08 max |

| Manganese (Mn) | 1.00 max |

| Silicon (Si) | 1.00 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.030 max |

| Chromium (Cr) | 11.5 – 14.5 |

| Aluminium (Al) | 0.10 – 0.30 |

| Nickel (Ni) | ≤ 0.75 |

| Iron (Fe) | Balance |

Technical Composition of Stainless Steel 405

Physical Properties of Stainless Steel 405

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Point | 1480 – 1530 °C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 24 W/m·K (100 °C) |

| Electrical Resistivity | 0.60 µΩ·m |

| Magnetic Properties | Fully Magnetic (Ferritic) |

Heat Treatment of Stainless Steel 405

| Process | Temperature Range | Purpose |

|---|---|---|

| Annealing | 760 – 815 °C | Restores ductility |

| Stress Relieving | 600 – 650 °C | Reduces fabrication stresses |

| Hardening | ❌ Not Applicable | Ferritic structure |

| Post-Weld Heat Treatment | Usually not required | Minimizes air-hardening |

📌 SS 405 does not harden by heat treatment. Aluminium prevents excessive grain growth and air-hardening during welding.

Mechanical Properties of Stainless Steel 405

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 380 – 540 MPa | 55,000 – 78,000 psi |

| Yield Strength (0.2%) | 205 – 275 MPa | 30,000 – 40,000 psi |

| Elongation | 20% | 20% |

| Hardness (Brinell) | 150 – 170 HB | 150 – 170 HB |

👉 SS 405 offers excellent thermal stability, oxidation resistance, and weldability, making it ideal for fabricated components exposed to heat.

International Standards & Equivalent Grades – SS 405

| Standard | Equivalent Grade |

|---|---|

| UNS | S40500 |

| AISI | 405 |

| EN | 1.4002 |

| DIN | X6CrAl13 |

| ASTM | A268, A240, A276 |

| JIS | SUS 405 |

| ISO | X6CrAl13 |

Products in Stainless Steel 405

MOKSH TUBES & FITTINGS LLP supplies a wide range of Stainless Steel 405 products in various forms. These products are widely used in industries such as Chemical Processing, Power Generation, Oil & Gas, Pulp & Paper, and many other engineering sectors. Stainless Steel 405 offers excellent oxidation and scaling resistance along with good ductility and machinability, making it suitable for applications that require moderate corrosion resistance and formability under elevated temperatures. It is an ideal material for components that must maintain mechanical integrity and durability in heat and mildly corrosive environments.

MOKSH TUBES & FITTINGS LLP supplies Stainless Steel 405 in a wide variety of product forms, including: