-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction to Stainless Steel 410 / AISI 410 / UNS S41000

MOKSH TUBES & FITTINGS LLP is a leading supplier, exporter, importer, and stockist of Stainless Steel 410 products, including pipes, tubes, sheets, plates, coils, bars, fittings, flanges, fasteners, wire mesh, and custom-engineered components.

Stainless Steel 410 is a martensitic stainless steel containing 11.5–13.5% chromium, designed for applications requiring good strength, moderate corrosion resistance, and excellent hardenability. Unlike ferritic or austenitic grades, 410 can be heat treated to achieve high mechanical strength and hardness, making it ideal for cutlery, valves, pump shafts, surgical instruments, and turbine parts.

It offers good resistance to atmospheric corrosion, mild chemical environments, and water, but is less resistant to more aggressive conditions compared to 304 or 316. However, its strength, machinability, and cost-effectiveness make it a widely used grade across multiple industries.

Download High Strength Stainless Steel 410 Datasheet

Get the complete High Strength Stainless Steel 410 datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – SS 410 / UNS S41000

| Property | Details |

|---|---|

| Material Type | Martensitic Stainless Steel |

| UNS Designation | S41000 |

| AISI | 410 |

| Chromium Content | 11.5 – 13.5 % |

| Carbon Level | Low–Medium |

| Heat Treatable | ✔ Yes |

| Maximum Hardness | ~45 HRC |

| Corrosion Resistance | Moderate |

| Magnetic Property | Magnetic |

| Typical Density | ~7.75 g/cm³ |

👉 The chromium content gives SS 410 its passive corrosion resistance, while carbon enables hardening through heat treatment.

Chemical Composition of Stainless Steel 410

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.08 – 0.15 |

| Manganese (Mn) | 1.00 max |

| Silicon (Si) | 1.00 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.030 max |

| Chromium (Cr) | 11.5 – 13.5 |

| Nickel (Ni) | 0.75 max |

| Iron (Fe) | Balance |

Technical Composition of Stainless Steel 410

Physical Properties of Stainless Steel 410

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Point | 1480 – 1530 °C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 24.9 W/m·K (100 °C) |

| Electrical Resistivity | 0.55 µΩ·m |

| Magnetic Properties | Magnetic (Martensitic) |

Heat Treatment & Hardening Cycle – SS 410

| Process | Temperature Range | Purpose |

|---|---|---|

| Annealing | 815 – 900 °C | Improves machinability |

| Hardening (Austenitizing) | 925 – 1010 °C | Prepares martensitic structure |

| Quenching | Oil / Air | Achieves hardness |

| Tempering | 150 – 370 °C | Balances hardness & toughness |

| Stress Relieving | 600 – 650 °C | Reduces internal stresses |

📌 SS 410 achieves the best balance of strength and toughness after proper quenching and tempering.

Mechanical Properties of Stainless Steel 410

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength (Annealed) | 450 – 650 MPa | 65,000 – 95,000 psi |

| Yield Strength (0.2%) | 275 MPa | 40,000 psi |

| Elongation | 20% | 20% |

| Hardness (Annealed) | 170 – 200 HB | 170 – 200 HB |

| Hardness (Hardened) | 35 – 45 HRC | 35 – 45 HRC |

👉 After heat treatment, SS 410 exhibits excellent mechanical strength, making it suitable for wear-resistant components.

International Standards & Equivalent Grades – SS 410

| Standard | Equivalent Grade |

|---|---|

| UNS | S41000 |

| AISI | 410 |

| EN | 1.4006 |

| DIN | X12Cr13 |

| ASTM | A240, A276, A479 |

| JIS | SUS 410 |

| ISO | X12Cr13 |

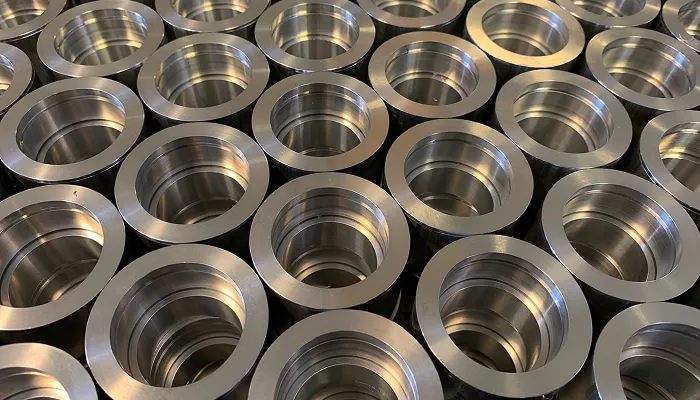

Products in Stainless Steel 410

MOKSH TUBES & FITTINGS LLP offers Stainless Steel 410 in a complete range of products, catering to diverse industrial, mechanical, and structural applications. From standard piping products to precision-engineered components, our inventory ensures reliable supply quality conforming to international standards.

All our Stainless Steel 410 products comply with ASTM A240 / A276 / A268 / A479 and equivalent international standards.

Uses and Advantages

Heat treatable for high strength and hardness

Good corrosion resistance in mild atmospheres and water

Magnetic properties suitable for industrial applications

Excellent machinability compared to austenitic grades

High wear and abrasion resistance after hardening

Cost-effective alternative to high-alloy stainless steels

Applications of Stainless Steel 410

Stainless Steel 410 is used across a broad range of industries for mechanical, structural, and wear-resistant components.

Cutlery & Kitchen Tools

Used in blades, knives, and utensils that require a sharp edge and durability.

Valves, Pumps & Shafts

Ideal for parts exposed to mild chemicals and water-based environments.

Turbine Blades & Steam Nozzles

Suited for high-strength applications under moderate heat and stress.

Automotive & Aerospace Parts

Used in shafts, fasteners, and components requiring wear resistance and precision.

Industrial Equipment

Applied in bolts, nuts, gears, bushings, and general hardware manufacturing.

Surgical & Dental Instruments

Suitable for instruments where strength, precision, and sterilization are required.

Why Choose Us

Stainless Steel 410 Price per kg in India

Typical Range: ₹230 – ₹580 per kg

(Price varies by OD, wall thickness, form, and finish)

Contact us for exact quotation based on size and quantity.

FAQ’s – Stainless Steel 410

What is 410 Stainless Steel?

410 is a martensitic stainless steel that provides good corrosion resistance, excellent hardenability, and high strength, making it ideal for engineering and industrial components.

What are its key properties?

It offers high wear resistance, hardness after heat treatment, moderate corrosion resistance, and excellent toughness for mechanical parts.

Where is Stainless Steel 410 used?

Commonly used in cutlery, valves, pump components, shafts, and turbine parts across industrial and mechanical sectors.

Is Stainless Steel 410 weldable?

Yes, 410 stainless steel can be welded with proper preheating and post-weld heat treatment to maintain corrosion resistance and mechanical properties.

Why choose MOKSH TUBES & FITTINGS LLP for 410 Stainless Steel?

MOKSH TUBES & FITTINGS LLP provides premium-quality 410 stainless steel products with precision manufacturing, extensive global delivery, and strict quality assurance for industrial customers worldwide.

blogs

Why High Strength Stainless St...

For decades, alloy steels such as EN19, EN24, 4140, 4340, and tool steels have dominated industries like aerospace...

High Strength Stainless Steel...

Choosing the right engineering material in 2025 is more complex than ever. Industries such as oil & gas, aeros...

Top Industrial Applications of...

High Strength Stainless Steels (HSSS) such as 17-4 PH, 15-5 PH, 13-8 MO, 440C, 431, and Super Duplex 2...Contact Us

For any inquiries or to request a quote, reach out to Moksh Tubes & Fittings LLP – your trusted partner for stainless steel 410 products.

Get in Touch