-

Call Us On

+91 97695 84950

-

Mail Us @

info@mokshtubes.com

Product Overview

Introduction to Stainless Steel 431 / Alloy 431 / UNS S43100

Stainless Steel 431 (UNS S43100) is a high-strength martensitic stainless steel known for its excellent corrosion resistance, toughness, and superior tensile strength. It is widely used in aerospace, marine, chemical, and automotive applications where both strength and corrosion resistance are key.

MOKSH TUBES & FITTINGS LLP supplies and stocks an extensive range of Stainless Steel 431 products, including pipes, tubes, sheets, plates, coils, flanges, fasteners, bars, rods, and precision-engineered components. It provides high resistance to mild acids, freshwater, and a variety of industrial chemicals. After heat treatment, this grade offers exceptional hardness and mechanical properties, making Stainless Steel 431 one of the most versatile grades in the 400-series category. The Stainless Steel 431 density is approximately 7.75 g/cm³, providing a balance between corrosion resistance, durability, and machinability.

Download High Strength Stainless Steel 431 Datasheet

Get the complete High Strength Stainless Steel 431 datasheet with chemical composition, mechanical properties, heat treatment details, and applications. Enter your email to receive the PDF instantly.

We respect your privacy. Your email will only be used to send the datasheet.

Material Summary – SS 431 / UNS S43100

| Property | Details |

|---|---|

| Material Type | Martensitic Stainless Steel |

| UNS Designation | S43100 |

| EN Equivalent | X17CrNi16-2 |

| Strength Level | Very High (Heat Treatable) |

| Corrosion Resistance | Good (Better than SS 410 / 420) |

| Heat Treatable | ✔ Yes |

| Weldability | Fair (with precautions) |

| Magnetic Property | Magnetic |

| Typical Density | ~7.75 g/cm³ |

👉 The chromium–nickel balance in SS 431 provides superior strength and better corrosion resistance than conventional martensitic grades.

Chemical Composition of Stainless Steel 431

| Element | Composition (%) |

|---|---|

| Carbon (C) | 0.20 max |

| Chromium (Cr) | 15.0 – 17.0 |

| Nickel (Ni) | 1.25 – 2.50 |

| Manganese (Mn) | 1.0 max |

| Silicon (Si) | 1.0 max |

| Phosphorus (P) | 0.040 max |

| Sulfur (S) | 0.030 max |

| Iron (Fe) | Balance |

This chemical balance provides excellent corrosion resistance, while carbon enables high strength after heat treatment.

Technical Composition of Stainless Steel 431

Physical Properties of Stainless Steel 431

| Property | Value |

|---|---|

| Density | 7.75 g/cm³ |

| Melting Point | 1450 °C |

| Modulus of Elasticity | 200 GPa |

| Thermal Conductivity | 25 W/m·K |

| Electrical Resistivity | 0.60 µΩ·m |

Heat Treatment & Hardening – SS 431

| Process | Temperature Range | Purpose |

|---|---|---|

| Annealing | 815 – 900 °C | Improves machinability |

| Hardening (Austenitizing) | 980 – 1050 °C | Prepares for quenching |

| Quenching | Oil / Air | Achieves martensitic structure |

| Tempering | 600 – 750 °C | Improves toughness & ductility |

| Stress Relieving | 600 – 650 °C | Reduces residual stresses |

📌 SS 431 achieves maximum strength only after proper quenching and tempering.

Mechanical Properties of Stainless Steel 431

| Property | Metric | Imperial |

|---|---|---|

| Tensile Strength | 850 – 1000 MPa | 123,000 – 145,000 psi |

| Yield Strength (0.2%) | 600 – 800 MPa | 87,000 – 116,000 psi |

| Elongation | 18 – 22% | 18 – 22% |

| Hardness (Brinell) | 230 – 300 HB | 230 – 300 HB |

International Standards & Equivalent Grades – SS 431

| Standard | Equivalent Grade |

|---|---|

| UNS | S43100 |

| EN | 1.4057 (X17CrNi16-2) |

| DIN | X17CrNi16-2 |

| ASTM | A276, A479 |

| AISI | 431 |

| JIS | SUS 431 |

| ISO | X17CrNi16-2 |

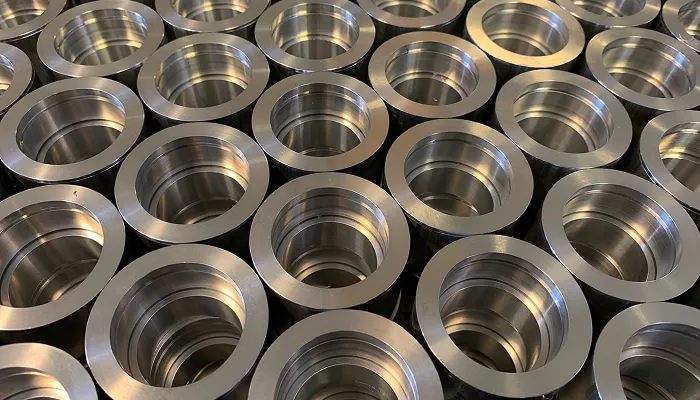

Products in Stainless Steel 431

MOKSH TUBES & FITTINGS LLP, with extensive experience in high-strength martensitic stainless steels and a strong supply network, offers a complete range of STAINLESS STEEL 431 products. These materials are designed for demanding applications in aerospace, marine, chemical, and automotive industries, where superior mechanical performance and corrosion resistance are essential. Our SS 431 offerings meet international quality standards, ensuring reliability, durability, and precision for both critical and general-purpose projects.

All Stainless Steel 431 products conform to ASTM A276, A479, A484, and other internationally recognized specifications.